Cabinplant News at Anuga FoodTec 2022 in Cologne: Multihead weigher for packing sticky convenience products – plus Integrated Blancher/Cooler that saves energy

![]()

Anuga FoodTec 2022: Stand F-039 (Hall 10.1)

At Anuga FoodTec 2022 in Cologne, Germany, Cabinplant A/S introduces two new solutions for the food sector. The MHW SF Extreme multihead weigher and packaging solution can handle sticky products such as poultry and fish. The new IBC Integrated Blancher and cooler with forced steam for fruit and vegetables can cut energy costs significantly.

Cabinplant A/S, innovative and global supplier of tailor-made food processing and weighing and packaging solutions, is ready to create a stir at Anuga FoodTec 2022. The company introduces the new, fully automatic MHW SF Extreme for the booming convenience food market to ease processing of extremely sticky products.

Highlights at Anuga FoodTec 2022:

- New generation multihead weigher: The fully automatic MHW Extreme facilitates weighing and packaging of sticky products, often used for the booming convenience food market

- Fruit and vegetable processing: The Integrated Blancher and Cooler (IBC) with forced steam will be exhibited for the first time at Anuga Foodtech. A unique principle with forced, circulated steam and re-circulation reduce the steam consumption and energy costs up to 50%. The solutions provide full flexibility between blanching by forced steam or traditional spraying with hot water.

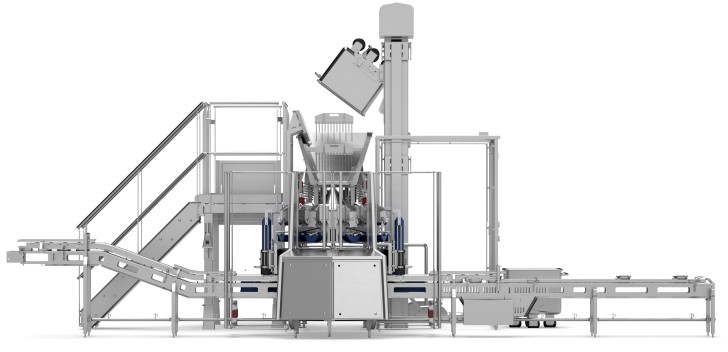

Fully automatic MHW Extreme: Weighing/packaging of extremely sticky products

Increased automation has been limited by the widespread use of sticky ingredients in ready-to-eat products, as automated packaging plants have not been able to manage them. So far, the limit has been reached for fresh products such as chicken and fish. Stickier products have stuck to the weighing machine, but this challenge is solved by a new patented solution from Cabinplant – the Multihead Weigher SF Extreme.

The new weigher combines Cabinplant's well-known screw-feeder combination weight with new scraper/weighing pans and a new processing solution, which ensures that the food is packed into trays on the conveyor belt. The MHW SF Extreme has a compact design making it easy to fit into existing production lines.

Further, the SF Extreme makes it possible to fully automate the dosing and packaging of ready-to-eat meals, which includes sticky ingredients such as diced vegetables, onion rings, rice, pasta, tuna fish, mayonnaise, yogurt, etc. These processes were previously performed manually or partially manually, without exact weighing.

- This is a technological breakthrough that breaks the boundaries of what has been possible so far with package lines and multihead weighers. Now the production of a large number of ready-to-eat meals can be fully automated, says Henning Ingemann Hansen, Director of Research and Development, Cabinplant A / S.

The MHW SF Extreme reduces the number of operator resources by 60-70 percent compared to similar packaging lines of convenience products including sticky products.

- The MHW SF Extreme removes a major bump in food manufacturers' roadmap, bringing a significant productivity jump and a new level of accuracy in weighing of extreme sticky product mixes thus reducing the labour force vulnerability of the production line significantly, concludes Michael Falck Schmidt, Sales Director at Cabinplant.

The end-product can be ready-to-eat meals packed in plastic trays, standing bags, etc. The cassettes can be replaced, which reduces the time for cleaning and changing to only 5-10 minutes and allows for frequent changes in recipes and packaging sizes at a time when the retail industry wants more varieties as well as more frequent and smaller deliveries.

Finally, during the pandemic the food industry has become aware of the vulnerability of labour-intensive production. The new weighing and packaging machine enables increased automation and reduces the food manufacturers' risks of involuntary stoppages.

Integrated Blancher and Cooler (IBC) – better quality, less energy consumption in fruit and vegetable processing

Integrated Blancher and Cooler (IBC) with forced steam is a unique solution from Cabinplant, a specialist with five decades of experience in equipment for blanching fruit and vegetables.

The use of forced, circulated steam and re-circulation reduces the steam consumption and energy costs up to 50% and potentially more due to the increasing energy costs. The solutions offer maximum flexibility between forced steam blanching and traditional spraying with hot water. Experience shows a pay-back time down to one year.

The processing time is fast and down to 3,5 minutes including the blanching up to 95 ℃ and cooling of the products down to 10 ℃. This ensures a high and uniform quality and maximum preservation of taste and nutrition. The Integrated Blancher and Cooler comes in different versions that can handle up to 30 tonnes per hour. Compared to traditional solutions productivity is several times higher.

In a preheating zone, the forced steam principle reduces steam consumption by 40-50% and recirculates the cooling water. This results in a reduction by up to 60% of the total energy costs. Forced steam with preheating pays dividends in just one year.

The IBC Blancher & Cooler is fitted with a Cleaning-in-Place system, where all internal parts of the machine are cleaned without having to be disassembled. Further, the conveyor belt continually goes through heat treatment, which helps to ensure a very high level of hygiene – almost eliminating the risk for bacteria like listeria in the processed fruit and vegetable products for the consumers.

- We are very proud of our IBC Forced Steam solution, which makes it possible to increase capacity and raise quality, and with a good return as well. The equipment continues the traditions we have at Cabinplant to strengthen the competitiveness of food producers, Michael Falck Schmidt, Sales Director at Cabinplant, sums up.

About Cabinplant

Cabinplant is a leading global provider of tailor-made processing solutions for the food industry. Focus areas are fish & seafood, fruit & vegetables, meat & poultry, and convenience foods. Additionally, Cabinplant provides multihead weighing and packaging solutions for a wide range of industries. In close cooperation with the customers, Cabinplant develops, manufactures, and markets innovative and complete food processing and weighing, packaging lines as well as single machines with built-in knowledge that optimizes yield, throughput, and product quality.

Cabinplant is a global company with headquarters in Haarby, Denmark, and employs more than 300 people. Subsidiaries in Germany, Spain, Poland, and the USA as well as a sales network of agents in more than 40 countries worldwide.

Founded in 1969 Cabinplant celebrated its 50th anniversary in 2019. In 2016, the American industrial company CTB, Inc., a Berkshire Hathaway company, took over 80 percent of Cabinplant’s shares to back up further expansion including the development of new products and partnerships. www.cabinplant.com