CSB-System Demonstrates Solutions For Efficiency And Traceability

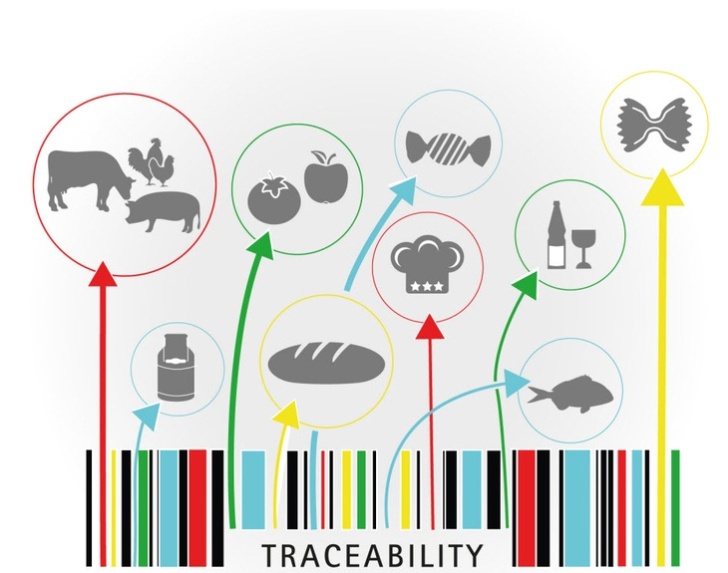

IT solutions for optimising production, providing automated data capture and ensuring full traceability for many different types of food products will be key highlights of the CSB-System stand at Process Expo.

IT solutions for optimising production, providing automated data capture and ensuring full traceability for many different types of food products will be key highlights of the CSB-System stand at Process Expo.

The company will demonstrate the capabilities of its Manufacturing Execution System (MES) which provides full control of production in real time, and the benefits of an integrated traceability system that links all areas of operation– from raw material procurement, processing and packing to onward despatch - through a single central database to monitor and report back on the progress or whereabouts of a product at any time.

Also on display will be the company’s CSB-Rack® industrial IT workstation for automated data capture that combines picking, weighing and price labelling in a single operation.

The CSB-System MES initiates, responds to and reports on all activities taking place in production, providing up-to-date information such as machine utilisation, stocks in hand and throughput times. This enables companies to react quickly to changing circumstances and reduces non-value adding activities, leading to optimised production and process flows. MES also helps to meet secure batch traceability requirements, and the ability to retrieve quality-related process data eliminates the need for any sub-systems.

CSB-System’s traceability software enables businesses to obtain International Food Standard (IFS) ‘higher level’ certification, meeting all legal requirements and providing an enhanced quality management system that helps to reduce costs and improve overall production efficiencies.

CSB-System’s traceability software enables businesses to obtain International Food Standard (IFS) ‘higher level’ certification, meeting all legal requirements and providing an enhanced quality management system that helps to reduce costs and improve overall production efficiencies.

The CSB system is also able to link to external consumer databases such as fTrace and Mynetfair to meet growing demand from end-customers to check the authenticity and history of the products they are purchasing.

Each traceability system is tailored to specific customer requirements taking into account particular national and international standards or regulations, including EU hygiene regulations, HACCP (Hazard Analysis and Critical Control Points) requirements, ingredients and nutritional information, and COOL (Country of Origin Labelling).

CSB says an integrated system also helps to reduce manual information inputting for enhanced accuracy and control of production, with online capture of data directly at source which in turn minimises the costs of documentation and labelling.

As part of the process, the CSB-Rack® is able to capture operating data online in real time at the point of origin, which is then directly imported into the CSB-System. From procurement of raw materials across all processing stages and quality management to complete labelling of the products, all traceability requirements are integrated in a way that reduces documentation expenses and keeps labelling to a minimum. In addition, by combining picking, weighing and price labelling in a single operation, unrelated, multi-stage processes in price labelling are eliminated.